Custom Merchandise Inventory: Scaling Best Practices

Managing inventory for custom merchandise can be challenging, especially when scaling. Here's what you need to know upfront:

- Key Challenges: Predicting demand, managing supply chain delays, and controlling inventory costs.

- Solutions: Use demand forecasting tools, real-time stock monitoring, and automated reordering systems.

- Core Methods: Implement just-in-time (JIT) practices, strengthen supplier relationships, and leverage AI for predictive analytics.

- Tools to Consider: Platforms like Stitchi offer features like global fulfillment, real-time tracking, and automated workflows to simplify scaling.

5 Essential Inventory Control Strategies for Efficient Operations

Core Inventory Scaling Methods

Scaling inventory requires systems that are both reliable and efficient. Today’s strategies combine data analysis with automation to streamline stock management and meet growing demands.

Demand Prediction Tools

Forecasting demand accurately helps avoid costly mistakes like overstocking or running out of key items. By analyzing past sales, seasonal trends, and external market factors, these tools provide actionable insights for inventory planning.

Here’s how demand prediction works:

| Component | Function | Business Impact |

|---|---|---|

| Historical Analysis | Examines past sales data to forecast demand | Reduces the risk of surplus inventory |

| Seasonal Mapping | Tracks cyclical trends for peak preparedness | Improves readiness during busy periods |

| Market Indicators | Monitors external factors influencing demand | Enables proactive inventory adjustments |

These insights form the foundation for real-time inventory tracking, ensuring businesses can adapt quickly to changes.

Live Stock Monitoring

Keeping track of inventory in real time is crucial for scaling operations. Modern systems allow businesses to see stock levels instantly, helping them avoid excess inventory and reduce carrying costs.

Features of live monitoring include:

- Automated alerts for low stock levels to prevent shortages.

- Location tracking for better visibility across warehouses.

- Supplier integration for automatic reordering when stock runs low.

With accurate tracking in place, businesses can process orders more efficiently.

Order Processing Improvements

Handling higher order volumes requires systems that are fast and precise. Automation plays a key role in speeding up order processing while minimizing mistakes.

Key improvements include:

-

Automated Verification

Order details are cross-checked with inventory levels automatically, reducing errors and avoiding overselling. -

Stock Management Integration

Real-time updates ensure all sales channels reflect accurate inventory, preventing double-selling or backorders. -

Smart Reordering

Automated purchase orders keep stock levels steady based on pre-set thresholds.

Platforms like Stitchi bring all these methods together, offering a unified solution for demand forecasting, live tracking, and order management to support growing businesses.

sbb-itb-6f489d9

Inventory Management Software Tools

Managing inventory today requires software that’s both powerful and easy to use. The best tools combine multiple features to help businesses efficiently handle custom merchandise operations. These tools simplify inventory processes and make scaling operations easier.

All-in-One Inventory Systems

Centralized inventory systems bring everything together - tracking inventory, analyzing sales data, and managing purchases - all in one place. This approach helps businesses maintain accurate stock levels and adapt quickly to market changes.

Here’s what these systems typically offer:

| Feature | Benefit | Key Function |

|---|---|---|

| Real-time Synchronization | Avoids overselling across platforms | Updates stock automatically |

| Supplier Integration | Simplifies reordering | Manages vendor relationships |

| Analytics Dashboard | Supports better decisions | Plans inventory using data insights |

To keep operations smooth, consider maintaining a 10-20% stock buffer and revisiting reorder points regularly. Next, let’s dive into a standout platform and how AI is shaping inventory management.

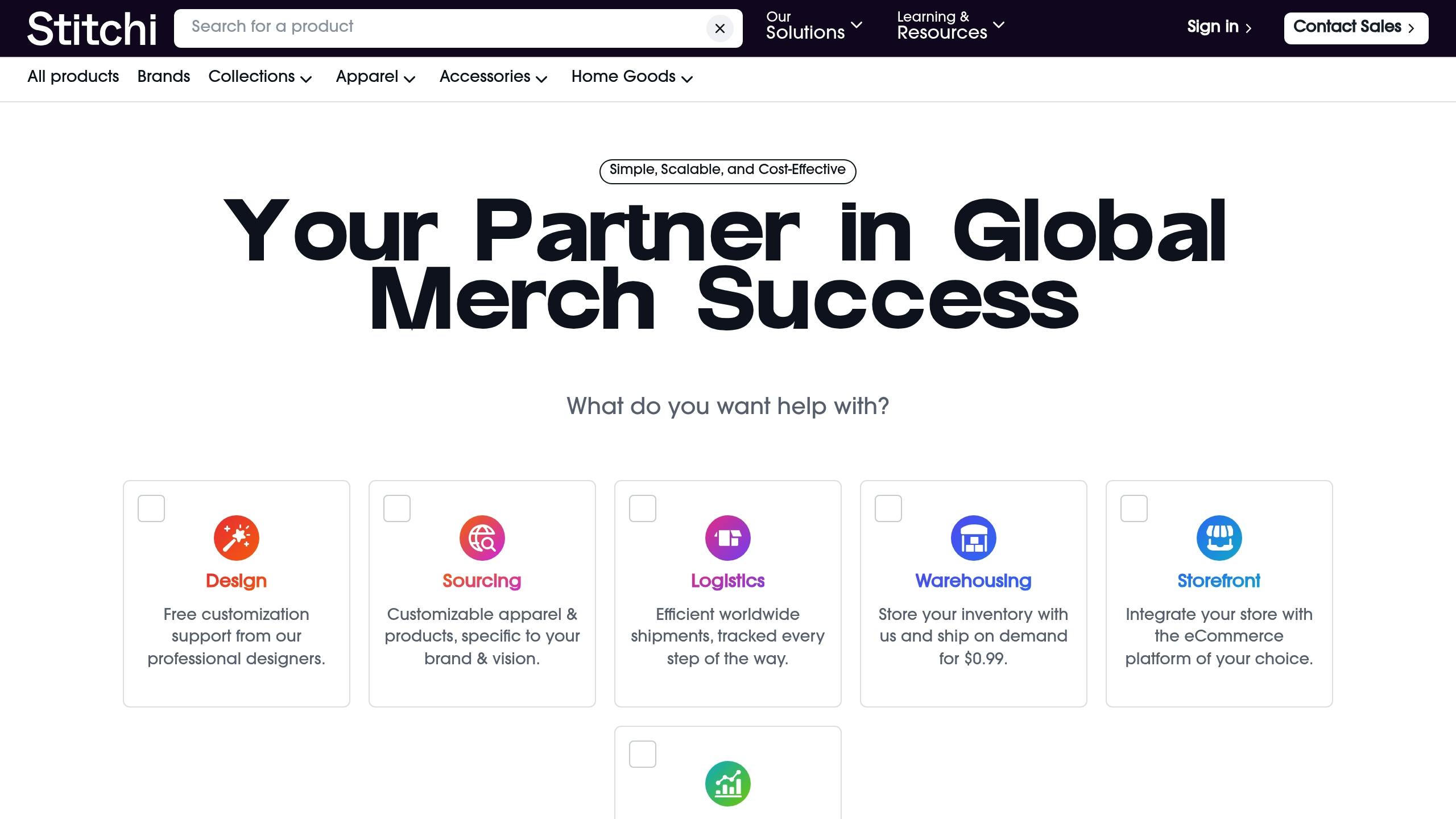

Stitchi Platform Features

Stitchi simplifies inventory management with tools like unlimited warehousing, global fulfillment, and print-on-demand quality checks. It’s designed to keep operations cost-effective and efficient.

Some of Stitchi’s standout features include:

- Unlimited storage and warehousing for flexible inventory needs

- Print-on-demand services with built-in quality checks

- Global fulfillment centers for faster delivery

- Customizable online stores with real-time inventory tracking

- Budget control workflows to manage costs effectively

AI and Automation Tools

AI and automation are transforming inventory management. Here’s how:

- Predictive Analytics: Uses past data to forecast demand

- Smart Reordering: Automatically places orders when stock gets low

- Real-time Monitoring: Tracks stock levels and movements continuously

- Data Integration: Links sales channels directly with inventory systems

To avoid errors, businesses should conduct regular audits and keep evaluating their automated systems. This ensures stock levels stay accurate and operations run smoothly across all channels.

Inventory Management Tips

Refining inventory control for custom merchandise operations goes beyond basic scaling and software tools. These practical tips can help you manage stock more effectively.

Stock Count Schedule

Consistent inventory checks are key to maintaining accurate stock records. Regular counts can quickly uncover any discrepancies, and the ideal frequency depends on your sales volume and how often inventory turns over.

Here’s a quick guide:

| Product Type | Count Frequency | Key Benefits |

|---|---|---|

| High-turnover Items | Weekly/Bi-weekly | Detect shrinkage early |

| Seasonal Products | Monthly | Improve forecasting accuracy |

| Low-turnover Items | Quarterly | Optimize resource allocation |

For the best results, combine cycle counting with full-scale audits. Assign specific days for counting certain product categories and ensure procedures remain consistent across all warehouse locations. Accurate data from these counts allows you to adopt more dynamic inventory strategies, leading to better profit margins.

Just-In-Time Stock Methods

Using accurate stock counts as a base, Just-In-Time (JIT) methods can help reduce excess inventory and streamline procurement. Keep a small safety stock on hand to handle unexpected demand spikes. Success with JIT depends on precise demand forecasting and solid supplier relationships.

Key practices for JIT success include:

- Leveraging real-time sales data to adjust production needs

- Tracking supplier lead times and updating safety stock as needed

- Setting up automated reorder triggers based on stock thresholds

Supplier Stock Management

Shifting inventory monitoring to suppliers can simplify your operations. Vendor-managed inventory (VMI) systems, for example, can reduce the administrative load while improving efficiency.

Here’s how to implement supplier stock management:

| Component | Implementation | Result |

|---|---|---|

| Communication Protocols | Regular updates and check-ins | Faster issue resolution |

| Performance Metrics | Monitor fill rates and lead times | Improved supplier accountability |

| Integration Tools | Link supplier systems to yours | Real-time inventory insights |

Start by applying this approach to your most dependable vendors, then gradually expand. Regularly reviewing supplier performance ensures high service standards and helps identify areas for improvement.

Summary

Modern, data-focused strategies are reshaping inventory management. Here's a breakdown of the key elements needed to scale custom merchandise inventory systems effectively.

Main Points

Managing custom merchandise inventory demands a mix of smart technology, efficient processes, and thoughtful planning. Success often hinges on using accurate demand forecasting tools and keeping stock levels visible in real time.

For better inventory control, businesses should prioritize these three areas:

| Focus Area | Key Components | Benefits |

|---|---|---|

| Technology Integration | Real-time tracking, AI-driven analytics | Reduces errors and improves accuracy |

| Stock Management | Just-in-time systems, automated reorders | Frees up cash and lowers holding costs |

| Supplier Relations | Vendor-managed inventory, performance reviews | Improves supply chain and reliability |

These areas work together to create a responsive and efficient inventory system that adapts to market needs.

Tools like Stitchi illustrate how combining warehousing, fulfillment, and real-time analytics can simplify scaling custom merchandise operations. This approach eliminates operational silos, making it easier to manage growth.

Data-driven strategies can lead to clear improvements. For example, setting reorder points based on precise demand forecasts ensures the right inventory levels. Whether you're starting with basic stock tracking or advanced AI forecasting, choose tools and processes that grow with your business while keeping operations smooth and efficient.