10 Essential Screen Printing Materials & Supplies

Screen printing requires the right tools and supplies for high-quality, durable prints. Here are the essential materials you'll need:

-

Screen Frames: Hold the mesh screen in place. Options include wood (cost-effective but prone to warping), aluminum (lightweight and durable), and retensionable frames (adjustable tension).

-

Screen Mesh: Forms the stencil for printing. Choose the mesh count based on design detail, ink type, and substrate. Higher counts (230+) are better for fine details, while lower counts (60-110) suit bold graphics and specialty inks.

-

Emulsion and Sensitizers: Light-sensitive coating applied to the mesh to create the stencil. Diazo, photopolymer, and dual-cure emulsions are available.

-

Exposure Units: Use UV light to harden the emulsion and create the stencil. LED units are energy-efficient and provide consistent exposure, while fluorescent units are more affordable.

-

Squeegees: Push ink through the mesh onto the material. Consider durometer (hardness), blade shape, and material (polyurethane, rubber, or composite).

-

Printing Inks: Water-based inks are eco-friendly but less durable, while plastisol inks are vibrant and durable but less eco-friendly.

-

Screen Printing Presses: Manual presses are affordable for low volumes, while automatic presses are faster for high-volume production.

-

Flash Dryers: Cure or "flash" the ink between color layers. Infrared (IR) dryers provide even heat distribution and faster curing.

-

Cleaning Supplies: Emulsion removers, degreasers, scrub pads, and pressure washers help keep screens clean for better print quality.

-

Conveyor Dryers: Ensure proper ink adhesion and durability by fully curing printed garments with continuous heat and a moving belt.

| Quick Comparison | Wood Frames | Aluminum Frames | Retensionable Frames | Diazo Emulsion | Photopolymer Emulsion | Dual-Cure Emulsion | LED Exposure Unit | Fluorescent Exposure Unit | Water-Based Ink | Plastisol Ink | Manual Press | Automatic Press | Coil Flash Dryer | Infrared Flash Dryer |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cost | Low | Moderate | High | Low | Moderate | Moderate | High | Low | Moderate | Moderate | Low | High | Low | High |

| Durability | Low | High | High | Moderate | High | High | High | Moderate | Low | High | - | - | Moderate | High |

| Precision | Low | High | High | Moderate | High | High | High | Moderate | Moderate | High | Low | High | Low | High |

| Eco-Friendliness | - | - | - | - | - | - | High | Moderate | High | Low | - | - | - | - |

| Ease of Use | High | Moderate | Low | High | Low | High | High | High | Moderate | High | High | Moderate | High | Moderate |

| Production Volume | Low | Moderate | High | Low | Moderate | High | High | Low | Low | High | Low | High | Low | High |

By investing in the right screen printing materials and supplies, you can create vibrant, long-lasting prints that satisfy your clients.

Related video from YouTube

1. Screen Frames

Screen frames hold the mesh screen in place during printing. The frame material affects durability, tension, and print quality.

Wood Frames

- Cost-effective: Good for beginners or tight budgets.

- Prone to warping: Moisture can affect print quality.

- Lower tension: Not ideal for finer mesh counts.

Aluminum Frames

- Lightweight and durable: Resists warping.

- Consistent quality: Suitable for high-tension applications.

- Higher cost: Long-term investment.

Retensionable Frames

- Adjustable tension: Ensures consistent print quality.

- High-volume jobs: Suitable for various mesh counts.

- More expensive: Requires skill to use.

Choosing a Frame

| Factor | Considerations |

|---|---|

| Application | Type of project (e.g., textiles, posters) |

| Image Size | Frame should be 2-3 inches larger than the design |

| Run Size | Durable and retensionable frames for large print runs |

| Equipment | Ensure compatibility with your screen printing press and exposure unit |

2. Screen Mesh

The screen mesh is crucial in screen printing, as it forms the stencil through which ink is transferred onto the material. The mesh count, measured in threads per inch, affects the detail and ink deposit of your prints.

Factors to Consider

- Design Detail: Higher mesh counts (230-305) are good for fine details and halftones. Lower counts (60-110) are better for bold graphics and specialty inks with larger particles.

- Ink Type: Thicker inks like plastisols and those with additives (glitter, puff) need lower mesh counts (60-110) to flow through easily. Thinner inks like water-based or discharge inks work better with higher mesh counts (200+) for a softer feel.

- Substrate: The material you're printing on matters. Tighter knit fabrics can handle higher mesh counts, while coarse or plush materials may need lower counts to push ink into the fibers.

General Guidelines

| Mesh Count | Use Case |

|---|---|

| 110 Mesh | Versatile for standard plastisol inks on textiles |

| 156-200 Mesh | Balances detail and opacity on textiles |

| 230+ Mesh | Fine details, halftones, and hard surfaces |

| 60-90 Mesh | Specialty inks with large particles like glitters or puffs |

Choosing the right mesh count ensures your design prints accurately and achieves the desired ink deposit and feel. Experimenting with different mesh counts can help you find the perfect balance for your projects.

3. Emulsion and Sensitizers

Emulsion is a light-sensitive coating applied to the mesh screen to create the stencil for screen printing. It hardens when exposed to UV light, allowing the design to transfer onto the screen. Choosing the right emulsion is key for good print quality and durability.

Emulsion Types

1. Diazo Emulsion

Diazo emulsions are a two-part system with the emulsion and a separate diazo sensitizer. The sensitizer is mixed into the emulsion to make it light-sensitive. These emulsions are easy to use and reclaim, making them good for beginners.

2. Photopolymer (SBQ) Emulsion

Photopolymer emulsions are pre-sensitized and very sensitive to UV/LED light. They are great for fine details and halftones. They expose quickly but can be tricky for beginners.

3. Dual-Cure Emulsion

Dual-cure emulsions combine diazo and photopolymer benefits. They offer a wide exposure range and fast exposure times. They are user-friendly and durable, making them popular among screen printers.

Choosing the Right Emulsion

| Factor | Considerations |

|---|---|

| Experience | Beginners may prefer dual-cure or diazo emulsions. |

| Exposure Unit | Diazo and dual-cure work with weaker units; photopolymers need stronger UV/LED units. |

| Ink Type | Water-based and discharge inks need emulsions with higher solids content. |

| Print Run Length | Longer runs may need more durable emulsions. |

Sensitizers

For diazo and dual-cure emulsions, a sensitizer must be mixed in to make them light-sensitive. Follow the manufacturer's instructions for mixing. Photopolymer emulsions do not need additional sensitizers.

Choosing the right emulsion and sensitizer is important for achieving good print quality and durability in your screen printing process.

4. Exposure Units

An exposure unit is key in screen printing. It hardens the emulsion on the screen mesh, creating a stencil for printing. The unit uses a light source to expose the emulsion-coated screen to UV light, hardening the emulsion where the artwork doesn't block it. This creates the image on the screen, allowing ink to pass through the open mesh areas during printing.

There are two main types of exposure units: LED and fluorescent. Each has its own pros and cons.

LED Exposure Units

LED (Light Emitting Diode) exposure units have many benefits:

- Energy Efficient: Uses less power, lowering costs.

- Long Lifespan: LED lights last around 50,000 hours or more.

- Consistent Exposure: Provides even exposure across the screen.

- Faster Exposure Times: Speeds up the process.

- Minimal Warm-up Time: Ready to use almost instantly.

While LED units cost more initially, their efficiency and long lifespan can save money over time.

Fluorescent Exposure Units

Fluorescent exposure units have been used for many years. They offer:

- Lower Initial Cost: More affordable upfront.

- Good for Basic Needs: Suitable for smaller print shops or beginners.

However, they also have drawbacks:

- Higher Operating Costs: Bulbs use more energy and need frequent replacements.

- Inconsistent Exposure: Can lead to uneven curing.

- Warm-up Time Required: Needs time to reach optimal exposure levels.

Comparison Table

| Feature | LED Exposure Unit | Fluorescent Exposure Unit |

|---|---|---|

| Cost | Higher initial cost | Lower initial cost |

| Durability | High (50,000+ hours) | Moderate (8,000-12,000 hours) |

| Precision | High (consistent exposure) | Moderate (uneven exposure) |

| Energy Efficiency | High | Low |

| Warm-up Time | Minimal | Required |

| Exposure Speed | Faster | Slower |

When choosing an exposure unit, consider your production volume, budget, and specific needs. LED units offer better performance and long-term savings, while fluorescent units can be a good option for smaller setups or those on a budget.

5. Squeegees

A squeegee is a key tool in screen printing, used to push ink through the mesh screen onto the material. Choosing the right squeegee is important for good print quality. Consider the durometer, shape, and material.

Durometer

The durometer measures the hardness of the squeegee blade. Common durometers are:

| Durometer | Description | Use Case |

|---|---|---|

| 60 | Soft blade | Thick ink deposits, special effects (puff, glitter), low mesh counts |

| 70 | Medium hardness | General printing, spot colors, halftones |

| 80 | Hard blade | Thin ink deposits, high mesh counts, fine details |

| 70/90/70 | Triple durometer | Combines 70 edge for ink deposit and 90 spine for pressure |

Blade Shape

Squeegee blades come in different shapes:

| Shape | Description | Use Case |

|---|---|---|

| Square | Sharp edge | Precise ink deposits, fine details |

| Round | Smooth ink release | Larger prints, softer edge |

| Single-Bevel | Angled edge | Better control, various applications |

Material

Squeegees are made from different materials:

| Material | Description | Use Case |

|---|---|---|

| Polyurethane | Durable, solvent-resistant | High-volume printing |

| Rubber | Affordable, less durable | Small print shops, beginners |

| Composite | Mix of rubber and polyurethane | Balance between durability and cost |

When selecting a squeegee, consider the durometer, blade shape, and material that best fit your printing needs. Proper maintenance, like cleaning and storing the squeegee correctly, can extend its lifespan and ensure consistent print quality.

sbb-itb-6f489d9

6. Printing Inks

Choosing the right ink is key for high-quality screen prints. The two main types of inks are water-based and plastisol inks, each with its own pros and cons.

Water-Based Inks

Water-based inks are eco-friendly and don't contain harmful chemicals. They provide a soft, breathable print that feels like part of the garment after washing. These inks are great for lighter-colored fabrics and achieving a vintage look. However, they may not be as vibrant on dark garments and might not be as durable as plastisol inks.

Plastisol Inks

Plastisol inks are made from PVC particles in a plasticizer, making them highly opaque and vibrant, even on dark fabrics. They are the industry standard for screen printing due to their excellent color vibrancy and durability. Plastisol inks are suitable for various fabrics, including athletic wear. However, they are less eco-friendly and can feel heavier on the garment.

Comparison Table

| Feature | Water-Based Ink | Plastisol Ink |

|---|---|---|

| Durability | Lower | Higher |

| Vibrancy | Moderate | High |

| Eco-Friendliness | Higher | Lower |

| Ease of Use | Moderate | High |

When choosing between water-based and plastisol inks, consider the fabric type, desired print characteristics, and environmental impact. For detailed designs on light fabrics, water-based inks may be better. For bright prints on dark garments, plastisol inks are often preferred.

7. Screen Printing Presses

A screen printing press helps you transfer designs onto items like t-shirts, bags, or banners. There are two main types: manual and automatic.

Manual Presses

Manual presses require you to do each step by hand:

- Apply ink to the screen

- Lower the screen onto the item

- Pull the squeegee across the screen to transfer the ink

- Lift the screen

- Rotate the pallet or carousel to the next station

Manual presses are good for small businesses, startups, or hobbyists. They are affordable and simple to use, ideal for low-volume production or samples. However, they can be labor-intensive and slow for large orders.

Automatic Presses

Automatic presses use electricity and air pressure to automate the printing process. You only need to set up the job and load/unload the items. These presses are faster and more efficient, making them suitable for high-volume production.

Automatic presses usually have more stations than print heads, allowing for dedicated loading and unloading stations. Some models can even create an extra unload station when needed.

Choosing the Right Press

When selecting a screen printing press, consider these factors:

| Factor | Manual Press | Automatic Press |

|---|---|---|

| Production Volume | Low | High |

| Number of Colors | Varies | Varies |

| Substrate Size | Varies | Varies |

| Budget | Lower cost | Higher cost |

| Space | Less space needed | More space needed |

The right press for your business depends on your production needs, budget, and available space. Consider both your current and future requirements to make an informed decision.

8. Flash Dryers

Flash dryers are used in screen printing to cure or "flash" the ink between printing each color layer. This prevents the ink colors from mixing and ensures proper adhesion between layers.

There are two main types of flash dryers:

Coil Flash Dryers

- Use coiled heating elements like an oven

- More affordable but can create uneven "cold spots"

- May require longer curing times and risk incomplete curing

Infrared (IR) Flash Dryers

- Use infrared heating panels for even heat distribution

- More expensive but provide consistent, efficient curing

- Eliminate cold spots and reduce the risk of undercured areas

- Preferred by professional screen printers for high-quality results

Comparison Table

| Feature | Coil Flash Dryers | Infrared (IR) Flash Dryers |

|---|---|---|

| Cost | Lower | Higher |

| Heat Distribution | Uneven | Even |

| Curing Time | Longer | Shorter |

| Risk of Cold Spots | Higher | Lower |

When selecting a flash dryer, consider:

- Production Volume: IR dryers are faster for high-volume printing

- Print Size: Larger dryers are needed for oversized prints

- Ink Type: Some inks may require forced air or chemical additives

- Budget: IR dryers have a higher upfront cost but improved longevity

Proper curing is key for vibrant, durable prints. Using the right flash dryer can improve print quality, efficiency, and consistency in your screen printing process.

9. Cleaning Supplies

Keeping your screens clean is important for good prints. Over time, inks and emulsions can build up, causing problems. Here are some key cleaning supplies you'll need:

Emulsion Removers

Emulsion removers help get rid of the emulsion coating on screens. Look for concentrated removers that you can mix with water to save money and reduce waste.

| Type | Description |

|---|---|

| Dip Tank Removers | Soak screens to dissolve emulsions. Effective but needs proper disposal. |

| Spray Removers | Good for spot cleaning. Often less harsh. |

Degreasers and Ink Removers

These help remove ink stains and other residues from screens.

| Type | Description |

|---|---|

| Biodegradable Degreasers | Eco-friendly, break down inks and oils without harsh chemicals. |

| Stain Removers | Tackle dried or cured ink stains. |

| Press Washes | Clean ink and residue from the print bed and other surfaces. |

Scrub Pads and Brushes

Scrub pads and brushes are useful for removing stubborn residues.

| Type | Description |

|---|---|

| Non-abrasive Scrub Pads | Scrub screens without damaging the mesh. |

| Stiff-bristled Brushes | Good for tight areas and dried ink or emulsion. |

Pressure Washers

A pressure washer can make screen cleaning faster and easier. The high-pressure water stream removes residues quickly.

Proper cleaning ensures better print quality and extends the life of your screens. Always follow the manufacturer's instructions and take safety precautions when using cleaning chemicals.

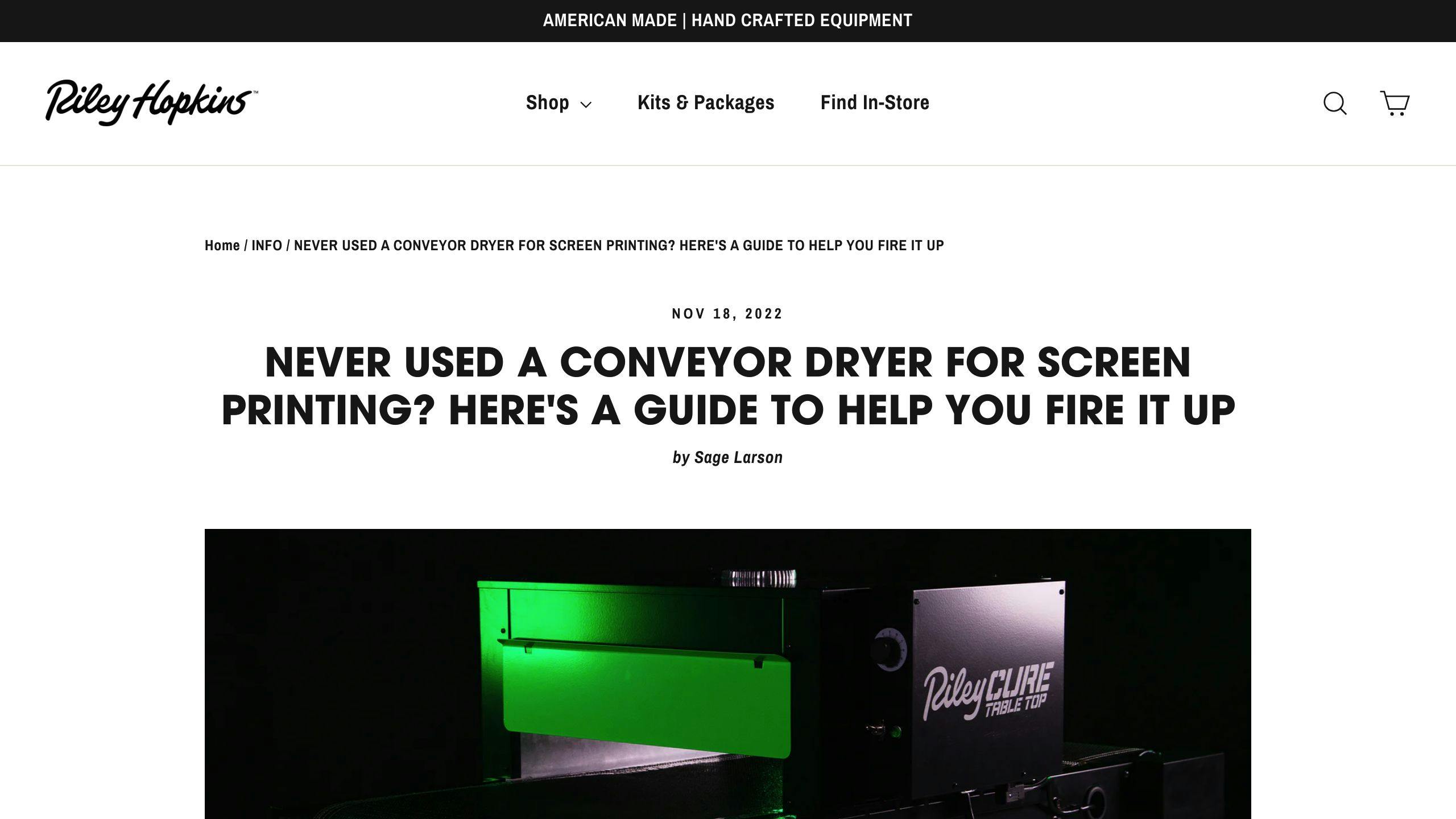

10. Conveyor Dryers

A conveyor dryer is crucial for curing screen-printed garments, ensuring proper ink adhesion and durability. Unlike flash dryers, which provide a quick burst of heat, conveyor dryers use continuous heat and a moving belt to fully cure the ink.

Advantages of Conveyor Dryers

| Advantage | Description |

|---|---|

| Consistent Curing | Even heat distribution and continuous movement ensure uniform curing. |

| High Production Capacity | Handles large print runs, ideal for commercial operations. |

| Precise Temperature Control | Allows setting and maintaining the optimal curing temperature. |

| Reduced Risk of Scorching | Minimizes the risk of overheating the ink or substrate. |

| Automation | Can be integrated into automated production lines for consistent results. |

Choosing a Conveyor Dryer

When selecting a conveyor dryer, consider:

| Factor | Considerations |

|---|---|

| Belt Width | Ensure it fits the size of your prints. |

| Heating Capacity | Match it to your production volume. |

| Ink Types | Check compatibility with water-based, plastisol, and discharge inks. |

| Adjustability | Look for adjustable belt speed and temperature settings. |

For high-volume screen printing, a conveyor dryer is a key investment, ensuring consistent curing, increased production capacity, and high-quality prints.

Conclusion

Screen printing is a rewarding process that needs the right tools and supplies for top-quality results. This guide has covered the key materials needed for successful screen printing, from screen frames and mesh to inks, exposure units, and curing equipment.

Investing in good materials is important for creating bright, durable prints that satisfy your clients. By choosing the right screen mesh, emulsion, and ink types, you can ensure accurate stencil creation and ink transfer, resulting in clear and long-lasting designs.

Having the right exposure units and curing equipment is also crucial for proper ink curing and adhesion, ensuring your prints last. Whether you're experienced or just starting, having the right tools and materials can greatly improve the quality and efficiency of your work.

FAQs

What is the basic equipment needed for screen printing?

The basic equipment needed for screen printing includes:

- Screen printing frames

- Screen mesh (polyester or stainless steel)

- Emulsion and sensitizer

- Exposure unit

- Squeegees

- Printing inks (plastisol, water-based, or discharge)

- Screen printing press (manual or automatic)

Other tools you will need include:

- Squeegees of a suitable size for your artwork and screen

- Ink scoops

- Spray bottles

- Empty containers to mix inks in

- Pallet adhesive

- Protective pallet tape and screen tapes

- Scoop coater to put emulsion onto screens

- Accurate scales

What is the most durable screen printing ink?

Plastisol ink is considered the most durable screen printing ink. Here are some key advantages of plastisol inks:

| Feature | Description |

|---|---|

| Versatile | Can be used on various materials like cotton, polyester, and blends. |

| Opaque | Provides excellent coverage and vibrant colors. |

| Durable | Highly resistant to cracking, fading, and washing. |

| Easy to use | Does not dry on the screen, allowing for longer print runs. |

| Crisp prints | Capable of producing detailed and sharp prints. |

Plastisol inks require heat curing to properly adhere to the substrate, but once cured, they offer superior durability compared to other ink types, making them the industry standard for long-lasting screen prints.